Application

© Long haul and building network communication

Operating Temperature

◎ -40°C~+70°C

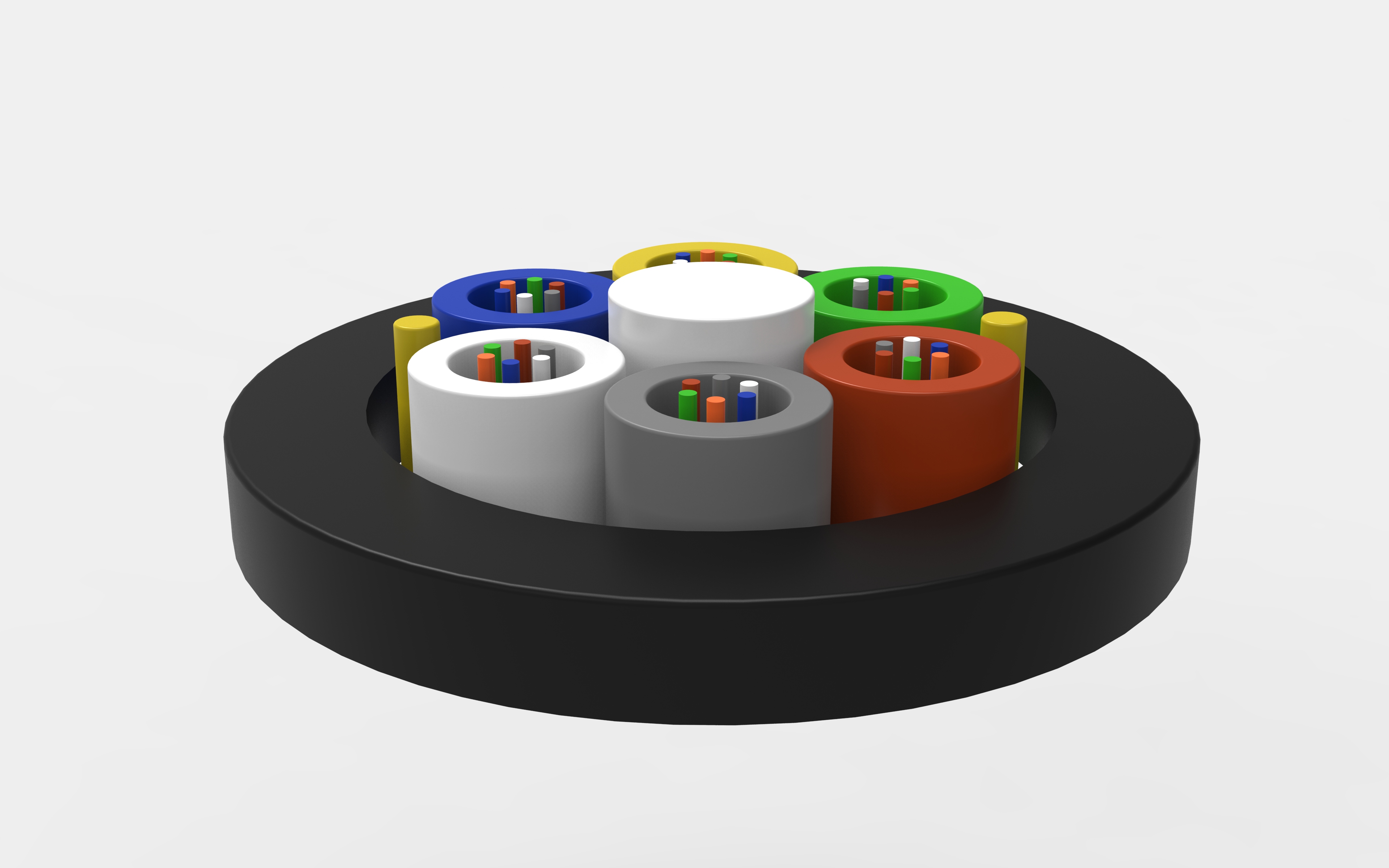

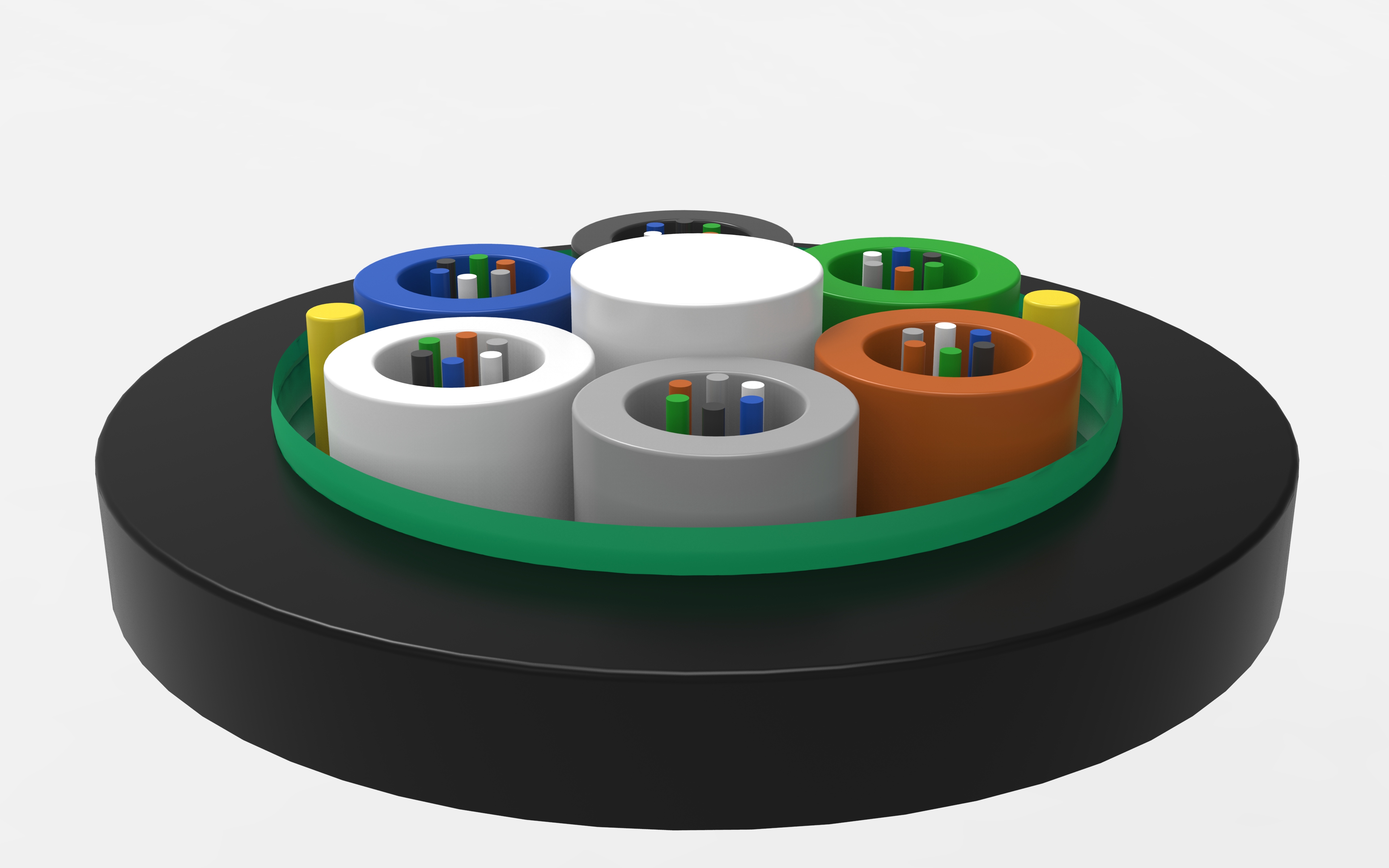

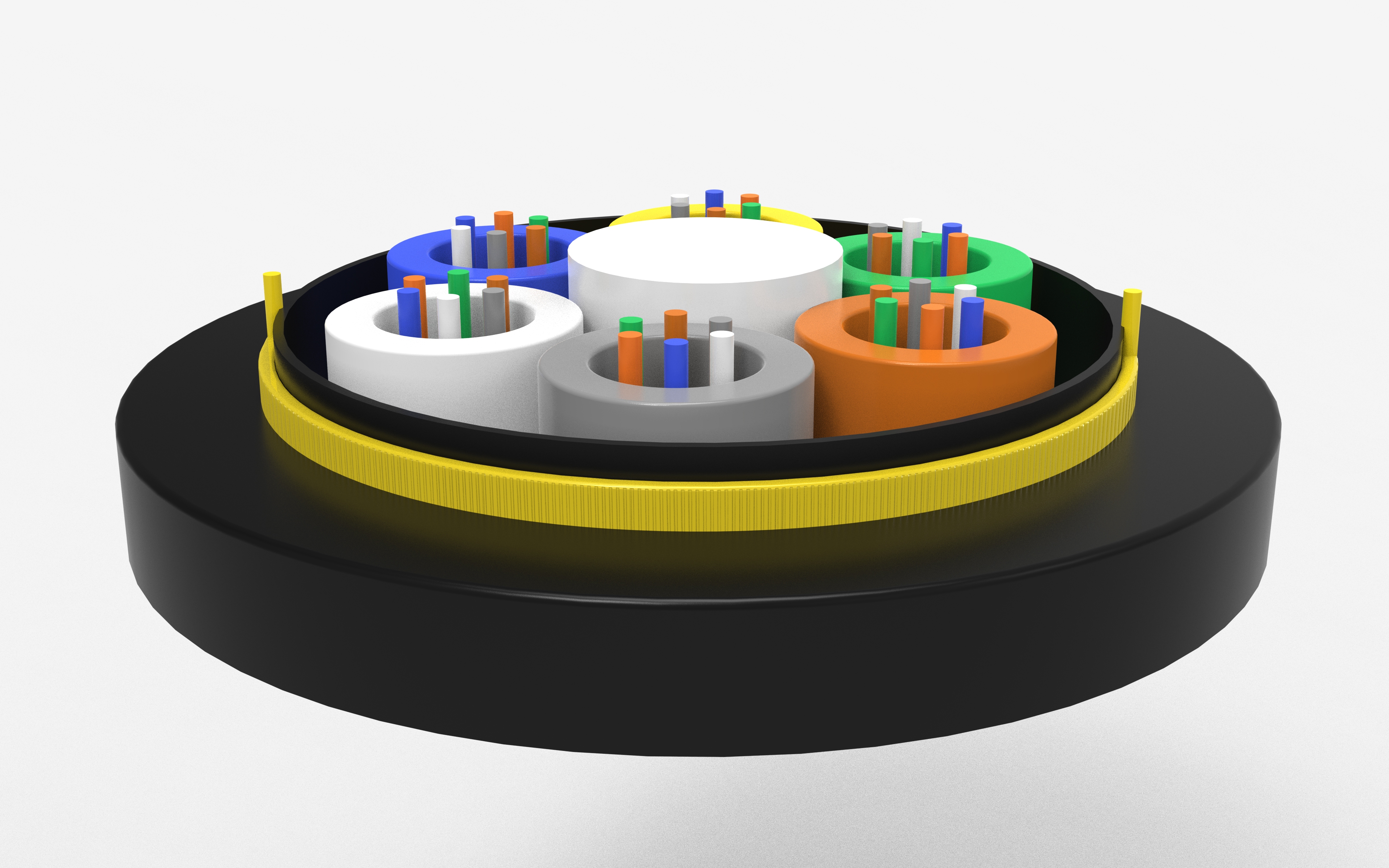

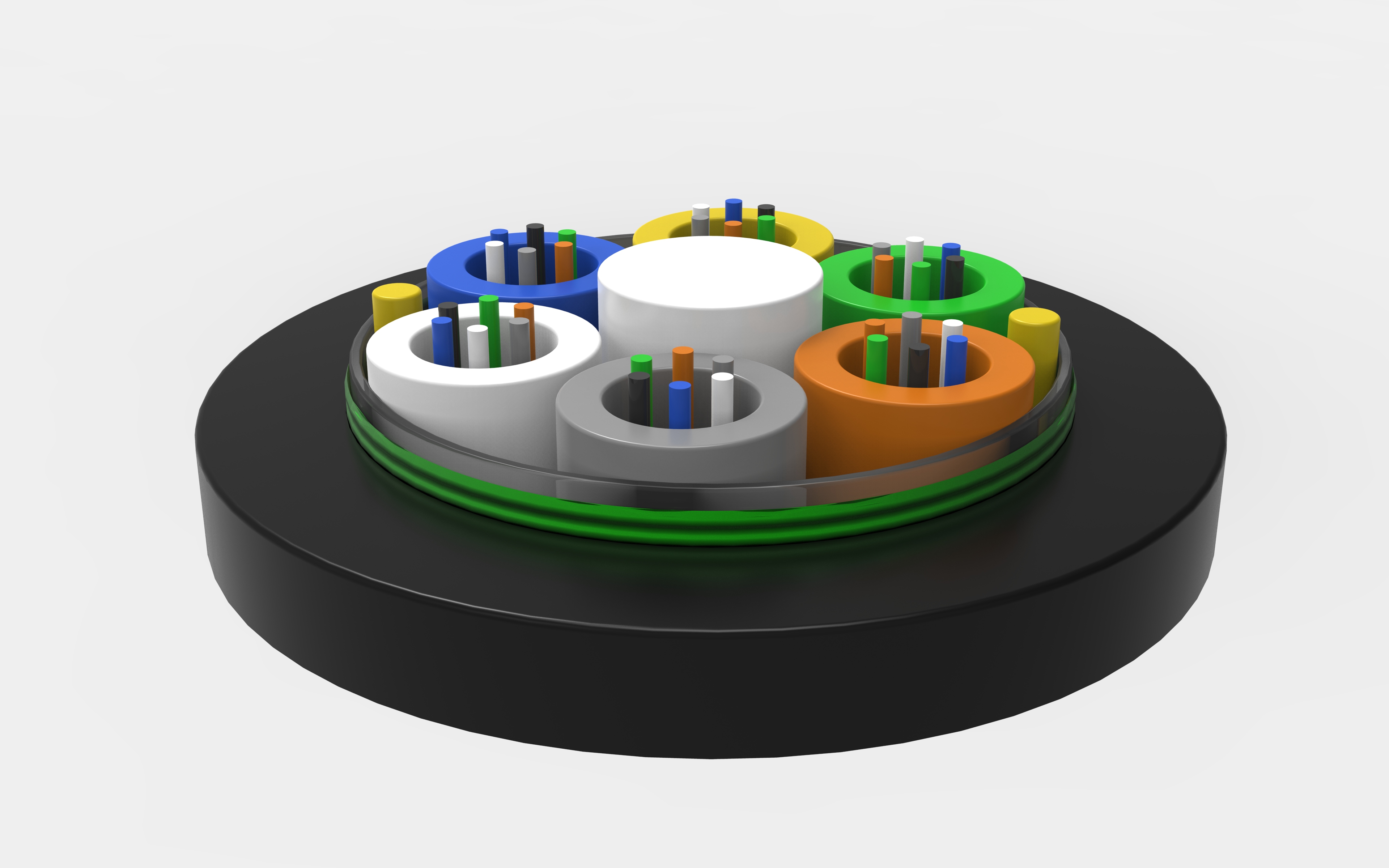

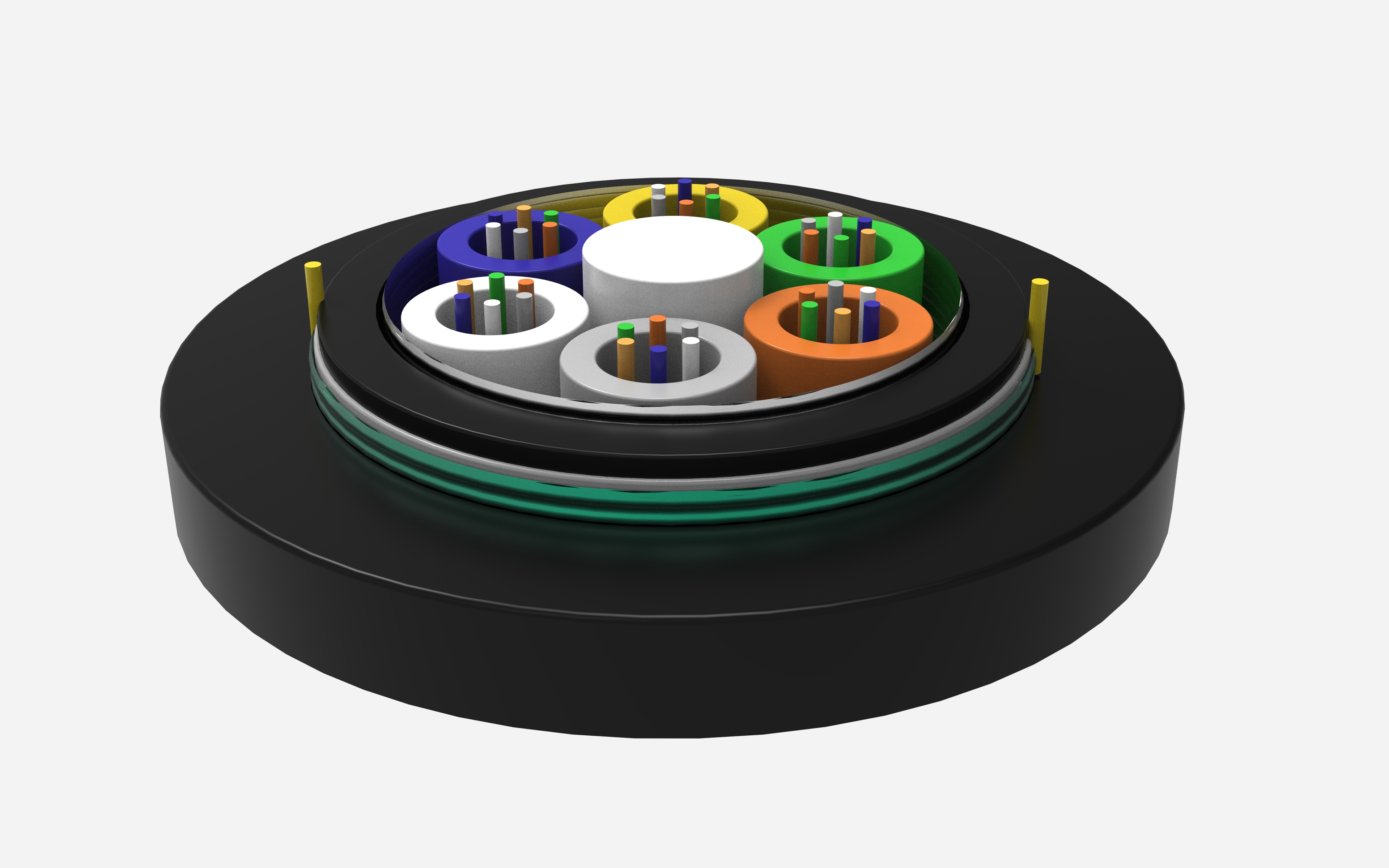

Water-blocking construction Moisture-proof and prevents water penetration

Special tube filling gel Reduce or eliminate reflection losses and prevent water penetration

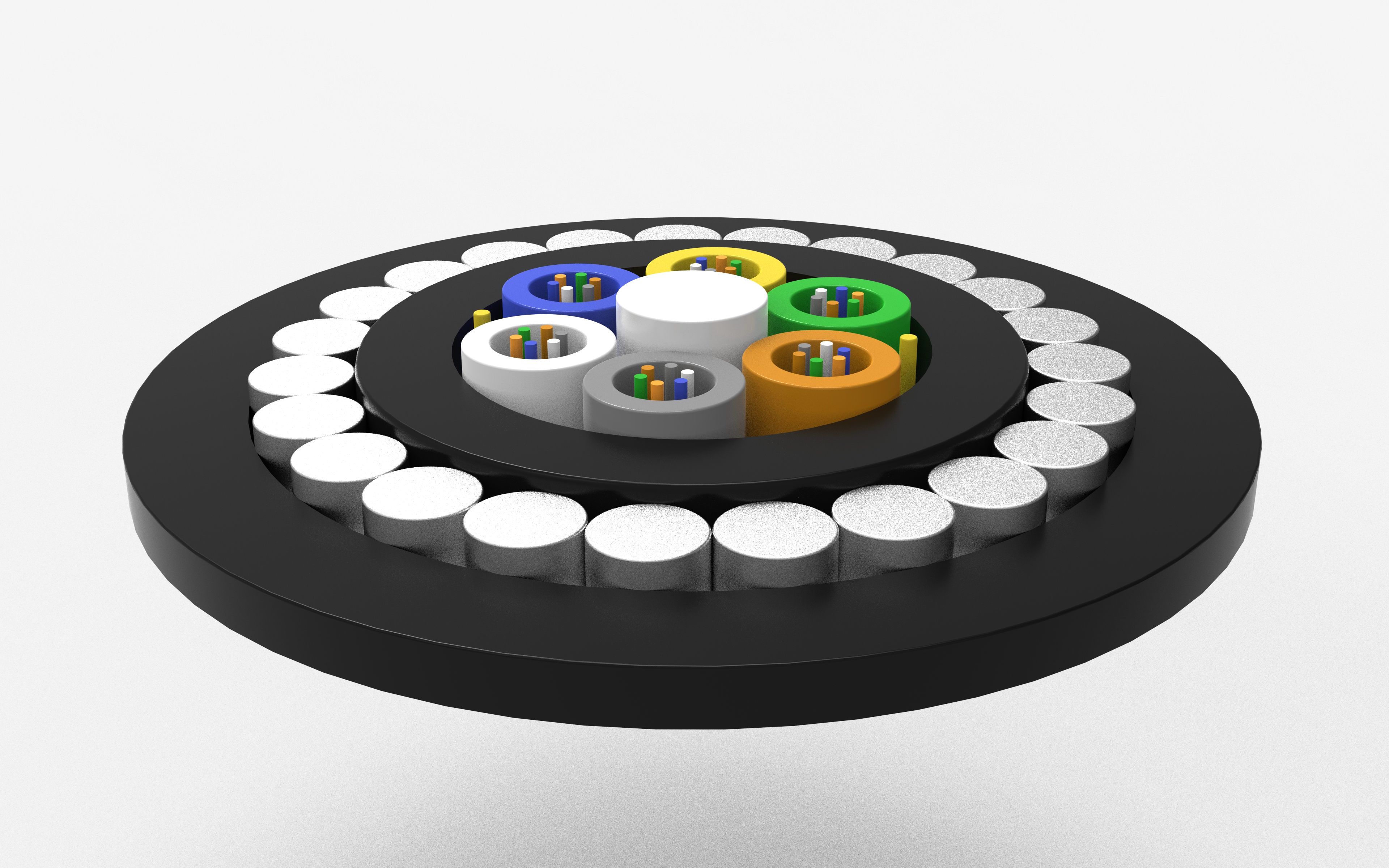

Fiber reinforced plastic as central strength member High Young's modulus

Longtitudinal coated steel tape High desirable tensile strength and crush resistance

Strict craft and raw material control Lifespan over 30 years

Customized longitudinal color strip Easy identification, packing and maintenance

Note:

©According to different applications, anti-termite optional.

© If loose tube stranded fiber cable is armored with aluminum tape, the type is GYFIA.

© For flame retardant cable, LSZH (Low-Smoke Zero Halogen) material is applicable to outer sheath and the type is GYFTZS/A.

© Longitudinal color strip on outer sheath can be provided according to customer's requests. More details, please refer to

GYFZA. © Special cable structure can be designed and manufactured upon customer's request.

Fiber Count | Nominal Diameter (mm) | Nominal Weight (kg/km) | Max Fibers per Tube | No. of (Tubes + Fillers) | Allowable Tensile Load (N) | Allowable Crush Resistance (N/lOOmm) | ||

Short Term | Long Term | Short Term | Long Term | |||||

2~36 | 11.4 | 130 | 6 | 6 | 1500 | 600 | 1000 | 300 |

38-72 | 12.5 | 152 | 12 | 6 | 1500 | 600 | 1000 | 300 |

74-96 | 14.2 | 194 | 12 | 8 | 1500 | 600 | 1000 | 300 |

98-120 | 15.7 | 230 | 12 | 10 | 1500 | 600 | 1000 | 300 |

122-144 | 17.3 | 274 | 12 | 12 | 1800 | 600 | 1000 | 300 |

>144 | Available upon customer's request | |||||||

•Customized cable staicture is available